Introduction

Worldwide, sunflower oil is one of the most widely used oils. The light-yellow oil is mainly used for frying and roasting. In combination with other vegetable oils, such as rapeseed oil, soybean oil, or linseed oil, it is also used as a salad oil, frying oil, or to make margarine.

The oil is typically extracted by applying great pressure to the sunflower seeds and collecting the oil. The protein-rich cake remaining after the seeds have been processed for oil is used as livestock feed.

Our company Evergreen Industry has invested in Sunflower oil production for its huge demand in Europe and the world. Furthermore, Sunflower oil is now the most used oil, because of not only benefits on our health but also it is good for cooking and can be reserved for longer periods.

Our company Evergreen has planted its sunflower machines production in Romania, this was made for a specific reason, Because not only Romania has great opportunities for launching projects but also Romania has been chosen for sunflower oil Project because Romania has constantly ranked first in the EU for sunflower crops since 2015, and the seed export potential is significant, taking into account that the domestic consumption needs a total of only 750,000 tons, according to Agerpres.

Before we land on Our Production Line, let’s discover the importance and significance of sunflower oil in the world.

Sunflower Oil In The global market

Why Romania

Romania remains the largest producer of sunflower in the European Union. In 2020, the country ranked first in the EU both in terms of production and cultivated area, according to provisional data from the National Statistics Institute (INS), quoted by local Agerpres.

According to INS data, next in the ranking of EU countries with the highest sunflower production is Hungary – with a total of 1.749 million tons and a cultivated area of 617,000 hectares, followed by Bulgaria – 1.66 million tons (810,000 hectares), and France – 1.655 million tons (775,000 hectares).

Romania has constantly ranked first in the EU for sunflower crops since 2015, and the seed export potential is significant, taking into account that the domestic consumption needs a total of only 750,000 tons, according to Agerpres.

Why Sunflower Oil Replacing other oil types

Fluctuating Prices of Other Vegetable Oils Drives the Demand

The sunflower oil is witnessing an upsurge in the global market, mainly driven by the fluctuating prices of other vegetable oils, such as palm oil, soybean oil, and others. The fluctuating prices often affect the overall sales of the end-user products; thus, firms are inclining toward stable-priced options like sunflower oil to utilize them for various purposes.

The manufacturers of snacks are readily opting for sunflower oil due to its capability to impart good properties to the products at a comparatively lower cost than olive oil. Moreover, the snack industries are choosing sunflower oil as a convenient alternative to palmolein oil as it does not require any kind of additional heating in cold temperature conditions, thus reducing the cost required for putting extra heating setup, unlike for palmolein oil, which has a higher freezing point.

The sunflower oil provides cost-effective solutions in other industries as well. Sunflower oil is rich in essential fatty acids and helps moisturize, regenerate, and condition the skin. Thus, it is considered for a variety of skin care products due to its lower pricing as compared to other nourishing oils, like argan oil, almond oil, and olive oil. Additionally, it is also used as the primary vegetable oil in bath oil and massage oil formulations.

Application of Sunflower Oil

-

Food

-

Snacks

-

Frying

-

Cooking

-

healthy diet

-

Industrial application

-

Cosmetic Formulations

Our Recomanded Project : Sunflower Oil Production Line

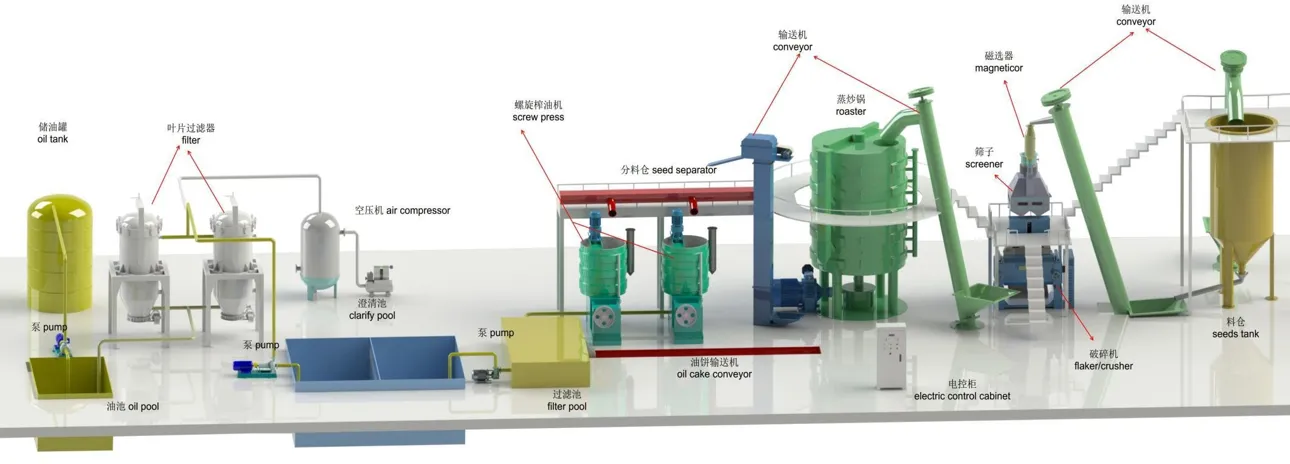

Main Process

-

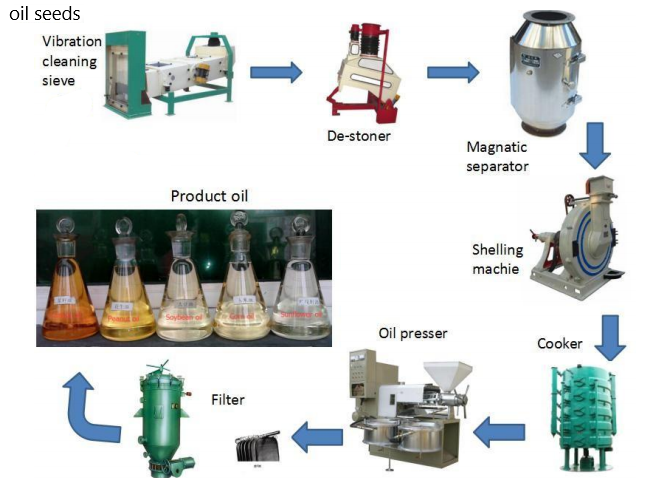

Cleaning

In order to make good quality of edible oil and oil cake, before pressing , the impurities need to be removed out of oil seeds. Generally speaking, in sunflower press workshop, vibratory cleaning sieve , de-stonner and permanent magnet drum are always used to clean the impurities in oil seeds, such as crop stalk, stone, magnetic metal, dust and other impurities which will influence oil quality, also in order to protect machine and make a clean working condition in workshop.

-

Crushing

After cleaning,in order to make the oil seeds granularity smaller and adjust the oil cake thickness, oil seeds shall be crushed into smaller pieces by crusher, thus creating a good condition for oil exrtraction.

-

Softening

The purpose of softening is to adjust water content and temperature of oil seeds, also to increase the plasticity of oil seeds. In this way, it can reduce the powder and glue stick phenomenon and guarantee good quality of flakers when flaking. Softening kettle is used in this process.

-

Flaking

Flaker is used in this part, it is the process of making use of the mechanical action to change the sunflower seeds from granularity into flakiness. After flaking, oil seeds cell wall is destroyed , thus shorten the oil outlet distance, also the materials is becoming thinner than before, it is good for material absorb moisture and heat in cooking process, and also it is much easier for getting oil in oil press process.

-

Cooker

The purpose of cooking is to adjust the moisture of oil seeds, thus make oil getting out easily. The purpose of cooking is to make the protein of oil seeds cell wall degenerated and then aggregated because of heated, increase the permeability of cell wall, and decrease the viscosity of oil, thus make oil come out easily, to make small oil drops into big oil Drops.

-

Pressing

The advantage of using press method to make oil is that, the support equipment is less, it is suitable for various oil seeds, such as sunflower seeds, soybean, groundnut, sesame, rapeseed , sesame, niger seed and so on. The production line is very flexible, the oil quality is pretty good with light color and good flavor.

-

Filtering

After getting crude oil from press process, there are some oil residue in it, it should be filtered by filter in order to get clean crude oil. After this process, clean crude oil can be pumped in to crude oil tank directly for storage.

Contact Us

- General Ali Riza gurcan caddesi. Bayaz AP.No 25.D:7 Merter- Istanbul-TURKEY

- Sfrikha@yahoo.com

- +90 531 730 93 84

- +40 774 424 323

- +216 25 697 000