Introduction

What is Thermoforming ?

Thermoforming is a process of heating a thermoplastic sheet to its softening point. The sheet is stretched across a single-sided mold and then manipulated. Then, it cools into the desired shape.

Thermoforming describes the process of heating a thermoplastic sheet to its softening point, stretching it over or into a single-sided mold, and holding it in place while it cools and solidifies into the desired shape. The thermoplastic sheet is clamped into a holding device and heated by an oven using either convection or radiant heat until it is softened. The sheet is then held horizontally over a mold and pressed into or stretched over the mold using vacuum pressure, air pressure, or mechanical force. The softened sheet conforms to the shape of the mold and is held in place until it cools. The excess material is then trimmed away and the formed part is released. Excess material can be reground, mixed with unused plastic, and reformed into thermoplastic sheets.

Examples of Thermoforming Products

Thermoform Applications

The thermoforming process can be used in a wide variety of applications as well. Some of the most common ones include but are not limited to:

- Retail clamshell packaging

- Packaging blisters

- Pick and place trays

- Material and handling trays and covers

- Shipping trays

- Medical packaging

- Pop displays

- Packaging inserts

Advantages of thermoforming

Thermoforming holds many advantages that make it a favorable process over other types of molding. Some of these advantages include:

-

The ability to create several finished parts from the same material.

-

It allows for the detection of possible design and fit issues before it is too late.

-

It saves time and money.

-

It is beneficial when using large parts.

Benefits of Thermoforming

-

Efficient

-

Cost-effective

-

Short lead time

-

Easy to add details

Primary Material

PP (Polypropylene)

This material has excellent chemical resistance. It is rigid and has good impact strength. It is good at higher temperatures but dimensionally is not as stable as other materials.

PET (Polyethylene Terephthalate)

This material is commonly used food packaging. It is clear and has a low cost. It can be FDA certified if needed.

PC (Polycarbonate)

This material has an incredibly high impact strength. It is clear and has a high-temperature resistance.

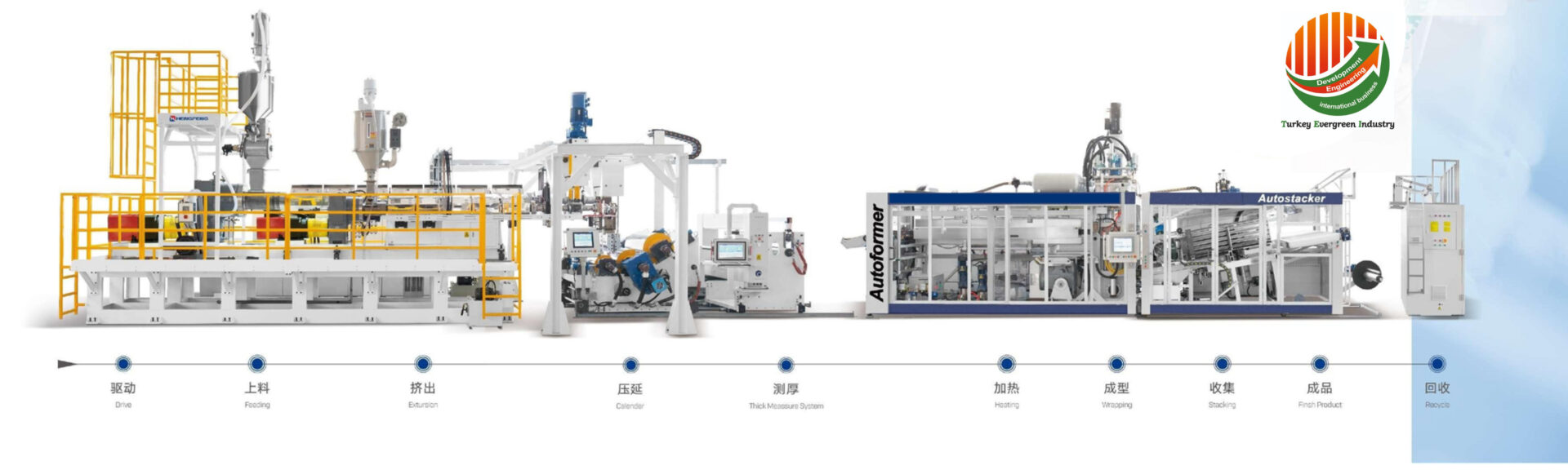

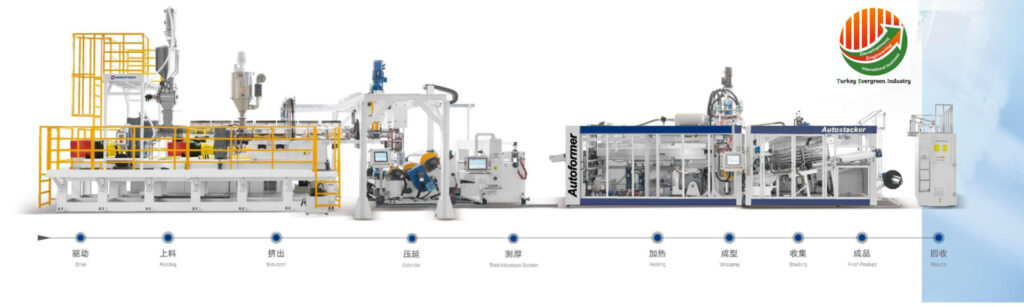

Our Thermoforming Project -Line -Machines

brief introduction

This Line guarantees high system performance in terms of production speed, management, saving, and the best hygiene conditions for food packaging production. Integrated new concepts and future trend technology control systems to ensure production efficiency and stability. Application: Suitable for PP. HIPS material to producing all kinds of plastic products, such as drinking cups. milk cups. water cups. bowls and containers etc.

Features

■ Man-interface operates, auto-assigned proportion feeding. extruding. pressing. forming. stacking and recycling processing is complete productions automatically.

■ Adjusting sheet width online and not required trimming for high utilization.

■ 7bar pressure and cutting in mould.

■ Automatic counting and stacking for more sanitary and save labor. Plug and feeding drove by Servo motor,

■ High speed: up to 45 analog beats/ min.

■ Mould with rapid change device and easy maintenance.

Lines And Machines (requirements)

- Sheet extrusion Line.

- Thermoforming Line (thermoforming + packaging or stacking ).

- Crusher series(for recycling).

Sheet Extrusion Line

sheet extruder Machine

Our Extrusion Machine is designed for high plasticizing. high yield and a variety of productions requirements, equipped with well-known brands parts ensure efficiency and stability. Applied Materials: Suitable for produce various plastic sheets of PP, HIPS, etc, which can be widely used for the plastic packing products industry.

Features

■ Optimize design for easy operation and maintenance.

■ A high degree of automation, man-interface for easy operation.

■ Screw with good plasticizing and high output after optimizing design.

■ Non-stop Extrusion production

■ Spiral groove design of Calendar roller with good cooling.

■ Calendar design with independent temperature controller system.

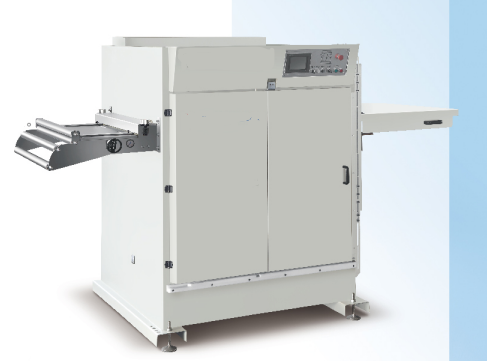

preheating machine

Preheating machine is used for heating thermoplastic material, especially polypropylene (PP) material, with fast heating and uniform heat distribution, this outstanding independent preheating system can be applied to any thermoforming ma-chine.

Features

■ Rapid Heating: attached is the roller for heating. thermal speed, low heat loss. ▪ Excellent permeability: attached the ratter for heating. Not scratch sheet: precisely synchronized transmission. low weight.

■ roller, without inertia. Excellent temperature distribution: attached the roller continuously • heating and long effective. ▪ Precise temperature control: not happen to overheat even machine shutdown.

■ Small footprint: compact design for the easy closing thermoforming unit. Independent control system: available for all kinds of thermoforming units.

Thermoforming Line

Thermoforming machine cup machine

the thermoforming machine guarantees high system performance in terms of production speed, management, saving, and the best hygiene conditions for food packaging production. This series thermoforming has the advantage of high yield, reliability, suitable for mass production. Integrated new concepts and future trend technology control systems to ensure production efficiency and stability. Application: Suitable for forming PP, PS, PET, PLC, PVC sheets that can produce all kinds of plastic products, such as drinking cups, milk cups water cups, etc.

Features

■ Driven by Cam more durable and faster after optimizing design.

■ Forming with 7bar air pressure. cutting in mould.

■ Automatic counting and stacking for more sanitary and save labor.

■ Plug and feeding are driven by Servo motor.

■ Maximum speed 45cycles per minute.

■ Mould with rapid change device. easy maintenance.

Thermoforming machine multi-utilisation

Multi-utilisation machine is a new series thermoforming of high-performance, high yield, high quality, high efficiency, lower consumption, suitable for mass production. Integrated new concepts and future trend technology control systems to ensure production efficiency and stability. Application: Suitable for forming PP, PS, OPS, PET, PLA, PVC sheets that can be widely used to produce all kinds of plastic containers Aids and trays, etc.

Features

■ Combination to different types, cutting in mould-stacking or forming-cutting-stacking or forming-punching-cutting-stacking depend on products.

■ All movements are driven by a servo motor. Forming, feeding, cutting, and stacking processing is complete

■ production automatically.

■ Mould with rapid change device, easy maintenance.

■ Forming With &Liar air pressure and vacuum.

■ Maximum speed 50 cycles per minutes.

Crusher serie

Crusher serie (recycling)

online Crusher Series are used for grinding the skeleton of sheet to flakes,then tranporting by the blower through pipe to extrusion hopper.ensure continuously production or can be customied according customer different requirements.

The whole employees will work hard to achieve its goals as follows.

I. To supply quality products.

2. To assure the conformity of the products

3. To keep perfecting the details and innovating technically .

Contact us today for thermoforming projects.

Contact Us

- General Ali Riza gurcan caddesi. Bayaz AP.No 25.D:7 Merter- Istanbul-TURKEY

- Sfrikha@yahoo.com

- +90 531 730 93 84

- +40 774 424 323

- +216 25 697 000